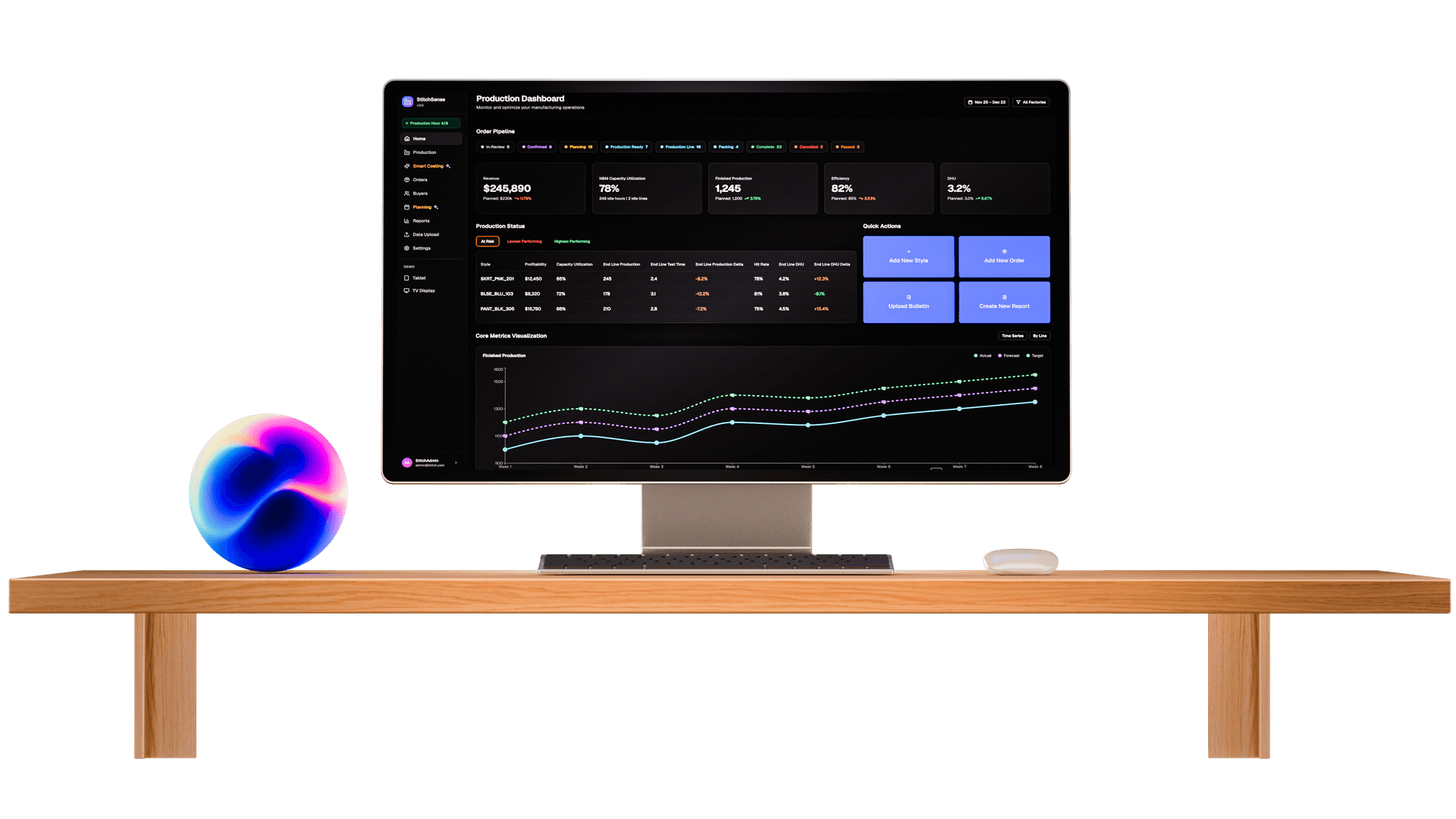

Your Co-Pilot forApparel Manufacturing

All-in-one merchandising, production & AI that grows your efficiency and profitability.

Integration

StitchSense AI

Merchandising

Production

StitchSense unites merchandising, production, & AI in one powerful platform, giving every manufacturer access to cutting edge prediction capabilities, enterprise-grade intelligence, dynamic production planning and its own digital workforce - to save time, cut costs & scale effortlessly.

Everything your business needs in one platform

Cost accurately, optimize planning, digitize your production, run your team & automate routine processes - with AI built for your business.

The connected, intelligent way

to manage your factory.

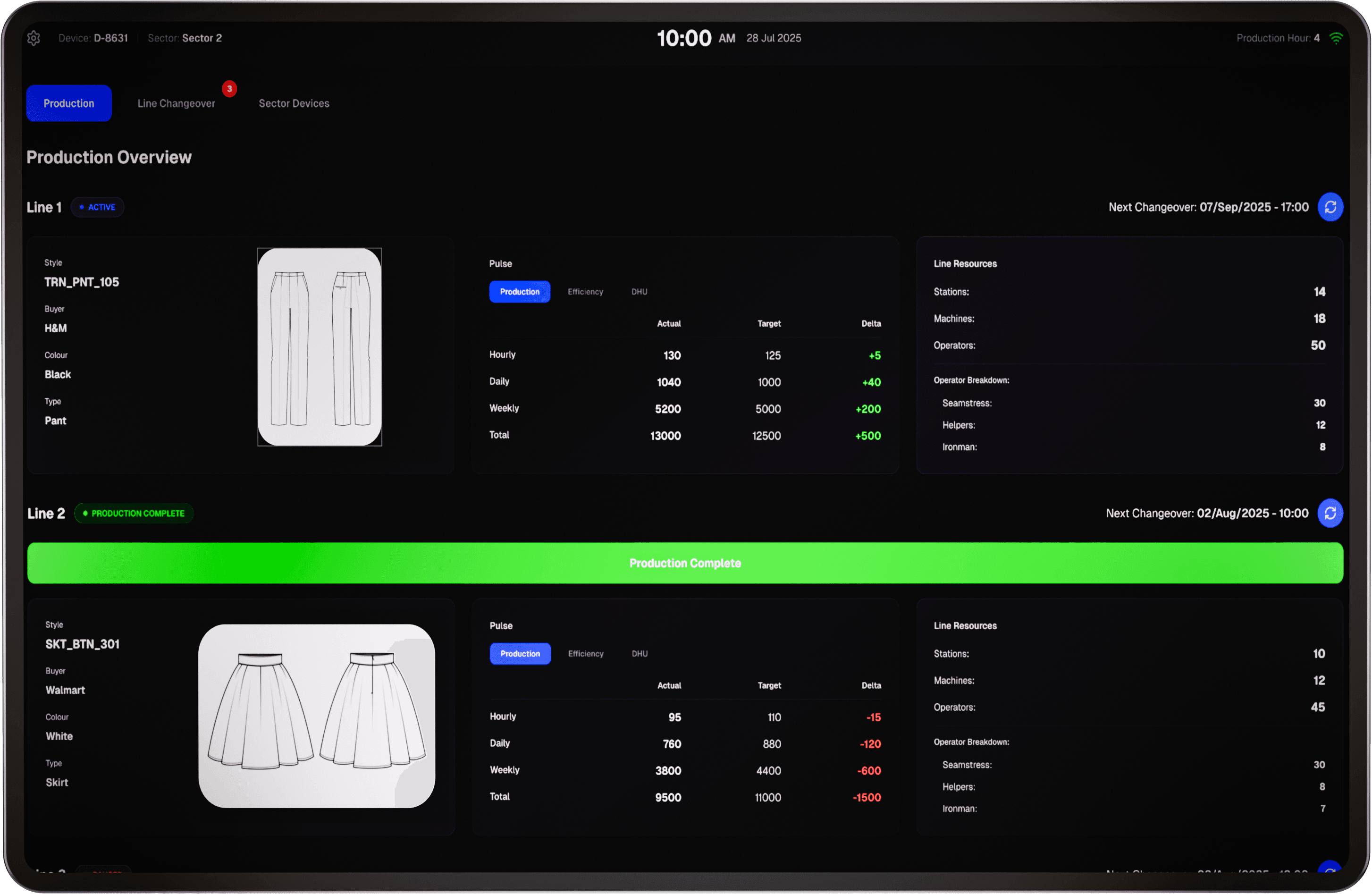

EDGESENSE

Collect operator and line data in real time, directly from the production floor. Simplify reporting, reduce defect rates, and empower data-driven action.

AI-driven intelligence for smarter factories,

tailored to your business, working 24/7.

From costing to production planning, StitchSense AI never stops working. It learns, predicts, and acts - giving your merchandising and production teams the edge to run a smarter, more profitable factory.

Discover what StitchSense can do for your business.

Built for the Future of Manufacturing

Accurate Production Data

Real-time visibility into every line, style, and shift—no delays, no guesswork.

Predictive Quality Analysis

Spot defect trends early and predict quality risks before they affect output.

Capacity Optimization

Most factories run far below their real capacity. StitchSense uncovers unused potential so teams can produce more with the same resources.

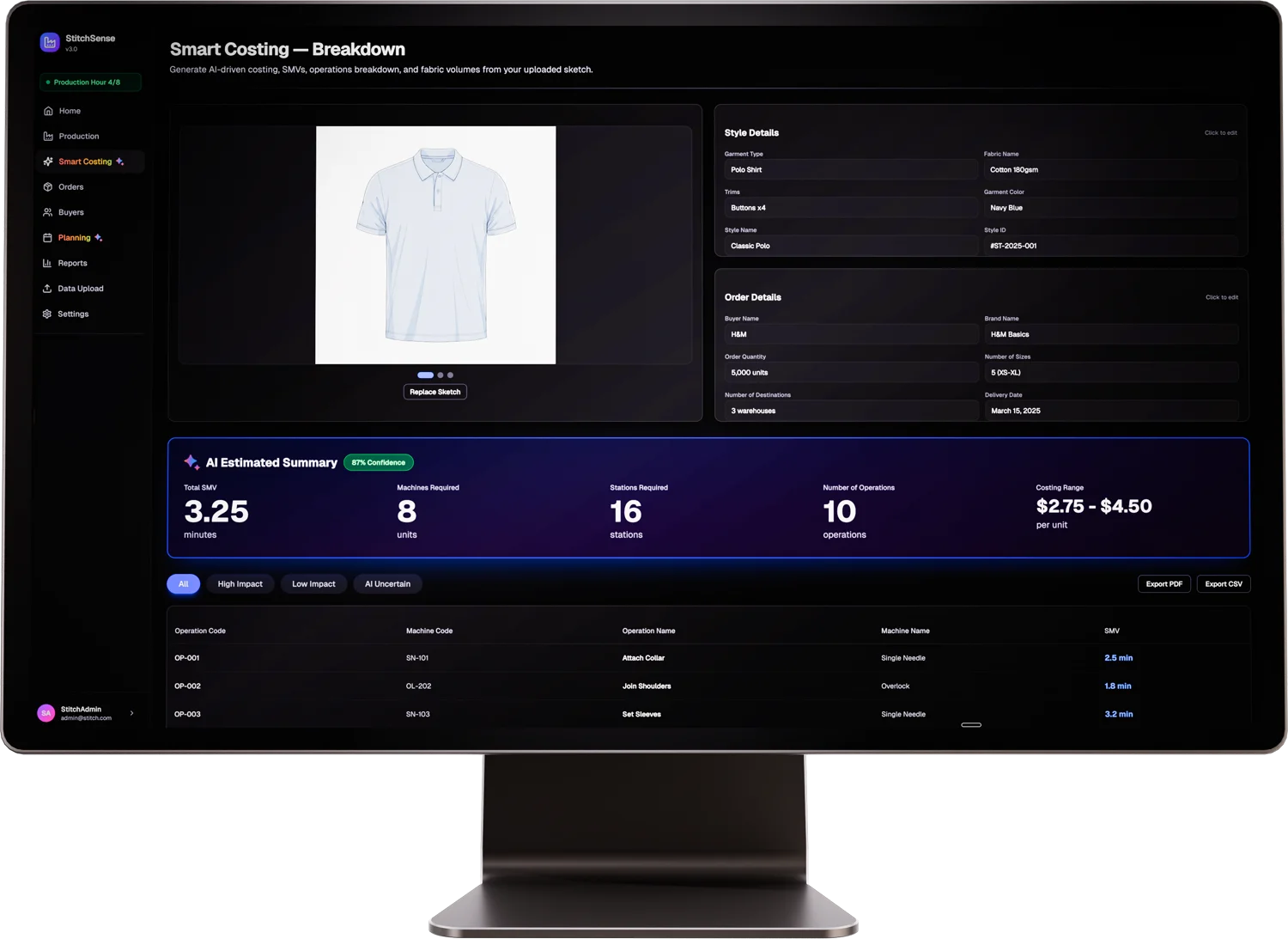

Smart Costing

Generate precise SMVs and cost ranges in seconds with AI that learns from your factory.

Predictive Bottleneck Detection

Identify slowdowns early and act before throughput drops.

Dynamic Production Planning

Planners lose hours reshuffling orders manually. AI now handles the complexity—so you can stay ahead.

Apparel Manufacturing, Reimagined.

Faster, Smarter, Simpler.

StitchSense captures every signal, from operators & machines to merchandisers & planners - and turns it into actionable insights that drive quality, efficiency, and margin growth.

Cost new styles with confidence. Generate SMVs and cost ranges instantly, with AI that learns from your styles, buyers, and factory.

More than just dashboards.

Real-time understanding & action.

Explore your data, receive smart alerts, and let StitchSense AI act autonomously — turning raw production signals into informed, real-time decisions.

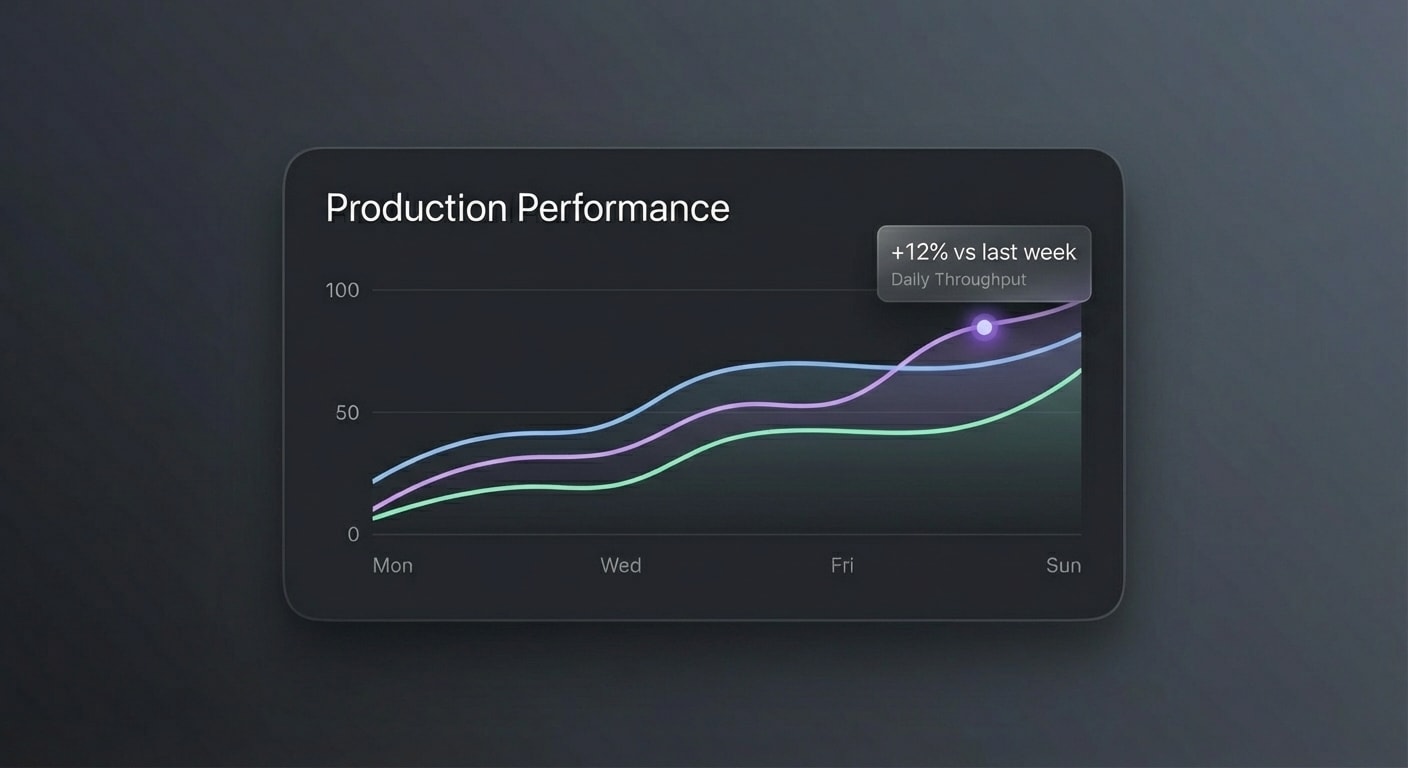

EXPLORE YOUR DATA

Ask questions, slice data, and uncover trends across orders, lines, and operations — without needing a data analyst.

VISUALIZE PERFORMANCE

Visualize live factory performance and historical benchmarks to understand exactly what's driving success or delay.